There's one more installment in the story 'till now, but first let's cover some recent events. I just completed my first carburetor rebuild. It took a bit over a month to get all the parts (don't cheap out on knock-off rebuild kits, boys and girls), but they're done and they work!

The SU Carburetor

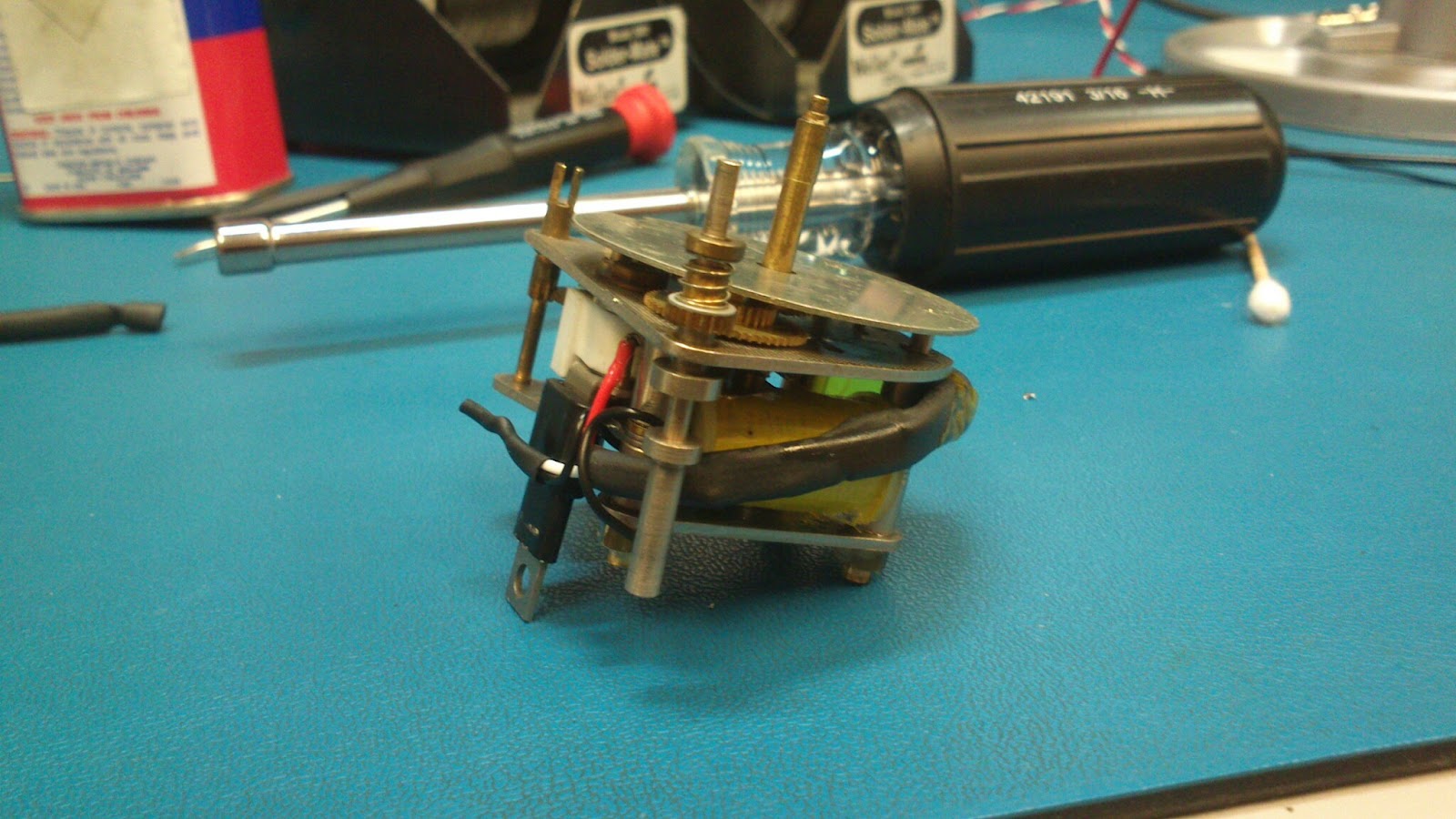

The carburetor has just one job: Mix fuel with the air that's being sucked into the engine. This involves four basic functions: interfacing with the fuel system (float bowls), metering the amount of fuel that goes into the air (needles and jets), ensuring the right amount of air/fuel mixture gets in to the engine (throttle), and providing a means to enrich the fuel mixture so the motor can start when cold (choke). I suppose there are endless ways to skin that cat and I'm sure I'll learn another way when I dig in to the dual Bing carburetors on my Airhead motorbike. It took some reading and perusing of the youtubes to demystify these little devices. From the outside, they are a chunk of metal with all sorts of tubes, springs, and appendages attached. I'll be honest, digging into them terrified me.

My Carbs After Rebuilding

Then I did some reading into how they work. Anybody with an old British import may be familiar with these little devices. They were designed back in the stone age by a company called Skinner's Union, then slowly refined a little at a time. The result is an extremely elegent and rugged design with few moving parts or delicate wear items. In essence, there is one moving part for each of the carburetor functions above.

In the float bowls, a plastic float opens and closes a needle valve to provide fuel to the system.

The fuel mixture is determined by raising or lowering a tapered needle in the fuel jet. For me, this is the most fascinating part of the design. The needle is at the bottom of a piston which moves up and down based on how much vacuum the engine is producing. More engine vacuum pulls up the piston, increasing the area the air can flow through while the taper on the needle increases the amount of fuel that can join it. The moving piston keeps a constant air velocity across the fuel jet, allowing the precisely tapered needle to accurately meter the amount of fuel it lets in.

Airflow to the engine is controlled via a standard throttle butterfly just downwind of the vacuum pistons.

Cold starting is achieved by both lowering the jets (so they interface with a narrower part of the tapered needle) to increase the fuel flow and slightly opening the throttles.

Rebuilding

Originally, I had picked up a set of Walker carb rebuild kits from Amazon, because, y'know, I'm cheap. After a few weeks of waiting for the back-ordered kits, I dug in to them. Dismantling the carbs starts with the piston covers (also called "dashpots" because British people are cheeky). Pull off the dashpots, catch the spring before it bounces away, pull out the pistons (careful of those needles!!) and dump out the old oil. Now a couple of bolts to remove the floats, a couple more for the bowls and jets. Two little screws come out of the throttle shaft allowing removal of the butterflies and shaft.

Everything gets a thorough soak in the bucket of death cleaner. Seriously, only use in a well ventilated environment. After a thorough wipe-down and a bit of polishing the exteriors with some steel wool, I got to rebuilding. I found my carb kits have an extensive selection of gaskets and seals, and my carbs themselves use perhaps four of them (actually, I needed six, but there was only one set of exhaust flange gaskets instead of the needed two). I went ahead and replaced what I had: needle valves in the float bowls, float bowl gaskets, dashpot damper gaskets.... I suppose that was it. The carb kits didn't seem to have quite the right air filter gasket either.

First issue: One of the jets has a cracked throat. This may have been why the car was parked, since there's no way to accurately meter the fuel. There's also chance that the little bronze throat got sucked into the engine and wreaked all sorts of havoc, but we're thinking happy thoughts. Of course, my carb kit doesn't have the jets. Luckily, proper SU branded kits are available through the current owner of the branding: Burlen. Now comes another two week wait for that to ship from England... Cheeky Brits...

In the meantime, let's put a better bandaid on that hole in the exhaust:

Only the best for my cars

That should do for now.

We Live Again!

The SU repair kit arrived and, strangely enough, has exactly the parts I would have needed in the first place with no extraneous gaskets or seals. Live and learn. I'll keep the gaskets for later since I just need the jets right now... New jets require re-centering the needle and jet. If the needles aren't perfectly centered, they'll rub on the jet throat, both ruining the fuel metering and rapidly increasing the wear on the needle and the jet. This means loosening and tightening the bolt that holds the jet to the bottom of the carb body over and over again until you can drop the piston and have it land with a "thud." Yes, that is the technical description of how to perform this vital task.

Needles centered, let's bolt it back together! But wait, there's another issue. For some reason, the prior owner had the throttle linkage so loose that it bound up on itself and wouldn't allow the throttles to close all the way. Perhaps they were trying to adjust the idle... A shot of PB-Blaster and some vise grips to loosen those rusty nuts and we're (finally!) back in business.

One final step - those dashpots need oil. The oil serves two purposes: 1) provide damping for the pistons to keep them from bouncing all over the place, 2) provide lubrication for the pistons which would otherwise be metal on metal against the dashpot covers. There is no consensus on what to oil to use here. All the internets tell me is "don't use water." Proper SU branded dashpot oil is available, but folks with these motors use everything from 5wt suspension damping oil to 20wt. Many recommendations I saw were for automatic transmission fluid (ATF), which I happen to have! Here's another valuable lesson, boys and girls, always read the label on that little blue bottle so you don't fill your dashpots with 30wt oil. Yeah, that'll pretty much keep em from moving...

There's still a lot of tuning to do. I'll need to check the valves and timing, then do an actual carb tune which I may even write up!

In the meantime, enjoy some sweet music: